Leading Oil & Gas Drilling Contractor Improves Life Safety Strategies by Use of Technology

- A Savance EIOBoard Client Case Study

"Before implementing this system on the Inspiration, I was excited about the thought of faster, more efficient emergency musters. We’ve been using it for several months now and the system has exceeded my expectations. "

Ken Davis, Radio Operator

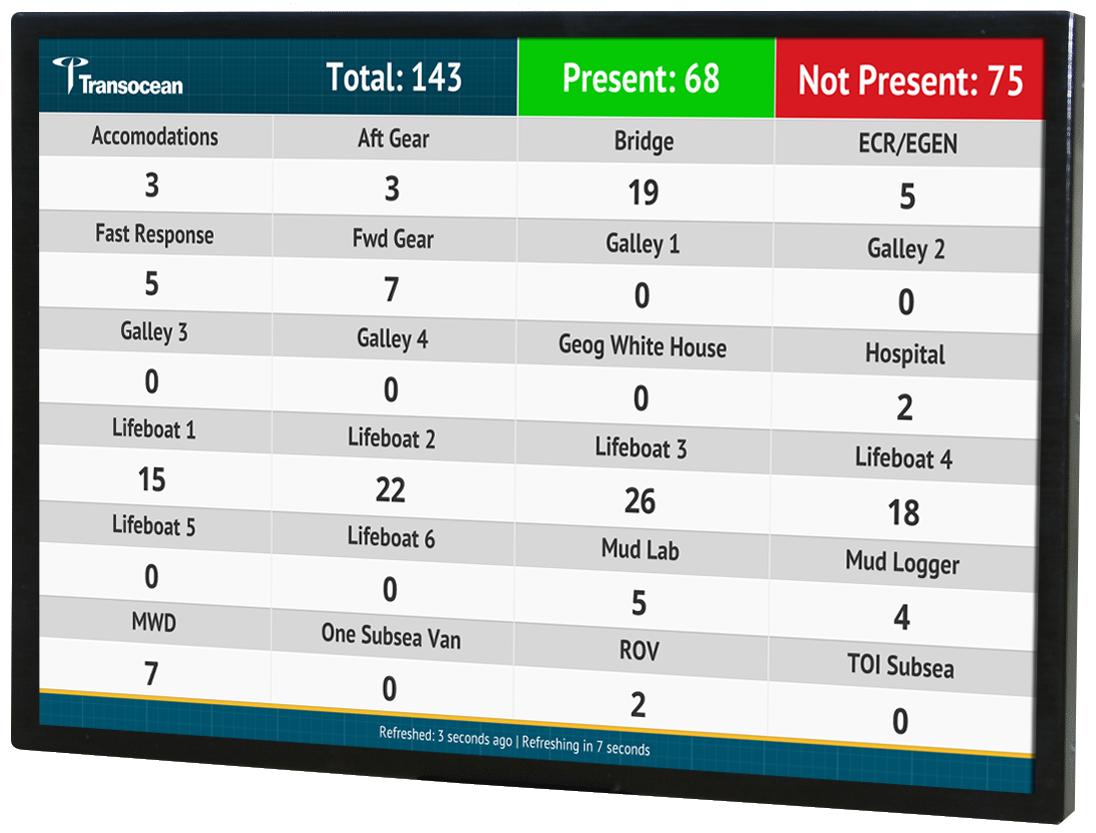

A custom large screen display board was designed to provide real-time muster point status updates at a glance

Background

Transocean is one of the world’s largest providers of offshore contract drilling services for the oil and gas industry, working with clients such as BP, Shell, Exxon, and Chevron. The company focuses primarily on deepwater and harsh environment services. It is a very dangerous process with many risks involved.

Challenges

In such a high-risk environment – where a single mistake can result in catastrophe – life safety is of the utmost importance. Accuracy and time could literally mean the difference between life and death for a large group of people, or even an entire 200+ person rig.

In 2010, Transocean's Deepwater Horizon exposed the world to a rig disaster in the U.S. Gulf of Mexico, where eleven lives were lost and several additional people were seriously injured. This event was subsequently made into a movie, released in 2016. Inaccurate musters led to an unknown number of missing people being reported to the United States Coast Guard. With the speed and automatic nature of an electronic mustering solution, this could have been avoided, and lives could have been saved.

With the goal of improving accuracy and speeding up the process of accounting for everyone on the rig, Captain Steve Walker initiated the project that would eventually lead to a custom electronic Emergency Mustering solution from Savance. In fact, the idea of improving the muster system for Transocean had been at the back of Walker’s mind for many years. “It was something that Transocean and I had been looking for, and working on, on and off for about 10 years,” he explains.

To this day, many Transocean rigs and other vessel-based operations rely on a paper and phone-based muster system to account for crewmembers and visitors aboard the rig at any time. There are several problems with this process, for instance:

"I wanted a reliable system that could provide full timely and accurate muster."

- It relies on paper that could be out of date and needs to be printed and distributed as it changes.

- It has the potential for human error.

- It is difficult and slow to identify exactly who is missing when a muster doesn’t match.

After trying several different methods for mustering, Captain Brandon Hargreaves of the Discoverer Inspiration had similar thoughts as Captain Walker when it comes to improving the system. “I wanted a reliable system that could provide full timely and accurate muster,” Hargreaves says. The previous methods were either too slow, or simply not reliable enough in the first place:

- Total Count Method: Each muster station would call up a number of personnel on scene, and hopefully it would add up to a full muster. If not, each muster station would call in each individual’s muster list number to determine missing personnel identity. “This method would require about eight to ten minutes if there was a full muster at each location, but could easily double if personnel were missing,” Hargreaves explains.

- T Card System: With the T Card system, each person had a card with their name on it that they would flip over to indicate that they were present at their lifeboat. Hargreaves and Walker explain that the T-Card system normally took longer than the call in method, and that it didn't work well, or at all, if personnel weren’t able to get to their assigned muster point. "It was also prone to mistakes and errors, which again could easily double muster times," Captain Hargreaves adds.

- Biometric Muster System: Finally, Hargreaves had tried a biometric muster system, but points out that this electronic fingerprint muster system was simply not reliable enough for their needs.

When using these other systems, Hargreaves’ priorities were not where he wanted them to be: “Using these other systems, I found myself spending much of my time attempting to get a good muster during drills and emergencies instead of thinking about how to properly react to the situation,” he explains. The final straw was a poor muster during a USCG inspection. “I knew there was a better technological solution to our mustering issue,” Hargreaves says, “[and this event] made me want to move forward with an electronic system.”

The Search

Although the paper- and phone-based muster process has been perfected – as much as is possible with a manual system – over the years, Captain Walker, like Captain Hargreaves, knew there had to be a more effective method. “Conventional systems work well for drills, but not so well in real emergencies,” he says. Captain Hargreaves agrees. “Obtaining an accurate muster is one of the most critical aspects of major emergency management on a drillship”, he explains. “While our system was fast, it was also prone to error if execution was not perfect.”

"Obtaining an accurate muster is one of the most critical aspects of major emergency management on a drillship"

Captain Hargreaves further points out that the chances of perfect execution with the confusion of an actual emergency is doubtful, and that a quick and accurate muster can be the difference between life and death. “A quick muster allows us to utilize fixed fire fighting, such as CO2, more quickly, and allows emergency response teams to focus on the fire or search and rescue more effectively, both of which can save lives.”

In addition to basic requirements such as muster speed and cost effectiveness, criteria for a new system included the system’s ability to account for people that are not at their assigned muster point. “Accounting for people is the most important thing during an emergency,” Captain Walker says, “and one of the things that can be the most difficult to manage is when people are unable to get to their ‘normal’ muster location during a real emergency.”

Captain Hargreaves provides additional criteria for a new muster system, including ease-of-use. “We needed a system that could be taught and used easily, allowing new crewmembers to utilize it within minutes of being onboard if necessary,” he explains. “We also needed a robust system that would still operate in case of any single or in some cases multiple failures. In addition, we wanted a system that could quickly communicate the needed information in an understandable form to the command team on the bridge, as well as the muster takers at the individual muster locations.”

In 2014, Captain Walker’s Internet search for electronic roll call solutions led him to Savance. “Other solutions were more expensive and I found operational issues with most of them,” he explains. After talking to Savance’s Steve Bardocz, it was decided that Captain Walker and Savance would work together to modify Savance’s electronic Emergency Mustering solution to make it suitable for offshore use by Transocean. The fact that Savance was willing to create a custom solution played a big part in Walker’s decision to move forward with the project. “The biggest selling point was [Savance’s] ability to modify the system to meet my needs,” he says. “When the many software change requests were made, Steve Bardocz never said ‘We can't do that’.”

Implementation

In discussions with Captain Steve Walker, who, at the time, served as the Marine Manager, Captain Hargreaves had on a few occasions expressed his interest in being the pilot vessel for an electronic mustering system. After starting the project, Captain Walker, who has since retired, put Hargreaves in contact with Savance to begin the process of installing the electronic mustering system (often referred to by the Inspiration as the ‘E-Muster System') on the Discoverer Inspiration.

On a vessel offshore, there are several situations that will determine how an e-muster system should operate, and this all needed to be taken into consideration when creating a custom offshore emergency management solution. Based on the situation, such as a fire, gas leak, or explosion, the severity will determine the process to muster:

- Situation 1 - Contained Emergency: Sometimes the first phase of a situation is to contain the problem, resolve it, and return to work. In this situation, a muster is initiated just to account for people, and to understand who may be at risk based on the situation and the location of concern. For example, if there is a fire, and they can be confident everyone is accounted for outside of the area of the incident, CO2 (which is an effective fire fighting agent but deadly to humans) can be deployed without the risk of adversely affecting crewmembers. Therefore, in an emergency situation like this, the first step is to take an immediate muster as quickly as possible. If the attempt to contain the situation fails, steps will be taken to move people to a different area or to abandon ship.

- Situation 2 - Multiphase Emergency: In this situation, a muster starts as in Situation 1, but the emergency gets worse. A decision is made to take extra evasive action to fight/contain the situation, and people may need to be moved and mustered again. This could happen multiple times in a very short period. Within an hour or two, you might need to do a full muster two or three times before you decide to abandon ship.

- Situation 3 - Uncontrollable Emergency (Abandon Ship): At any point, the captain may determine that the situation is out of control and decide to call for an Abandon Ship. This can happen immediately but the situation may also escalate to this point. Abandon Ship is the last resort. At this point, each person goes to their assigned lifeboat muster point if possible, or to the closest one they can safely reach. Each lifeboat is designed to hold 50+ crewmembers and the Inspiration has more than double the needed lifeboats to make sure they always have enough in situations where certain lifeboats are not accessible. At this point, one last muster is done to make sure all crew are accounted for before boats are loaded and sent off on the captain's orders.

Custom muster tablet with Pelican case, designed to hold tablet and prox reader. » Learn more

Initially, the goal was to just handle Situation 3, Abandon Ship, and the plan was to put endpoints by the lifeboats and have a master station on the bridge that would manage the system, check people in and off the rig, and monitor the muster.

Further discussions determined that the endpoints should be battery-operated and ideally removable/portable. For that reason, instead of fixed touchscreen PCs, Savance developed a custom tablet solution inside a Pelican case for each of the exterior endpoints. The endpoint was designed to be Power over Ethernet (PoE) so you could simply plug in one quick-disconnect, twist style CAT 6e cable to both power and network the device. In addition, a prox card reader was integrated into the device for quick mustering.

After the initial pilot, a few items for feedback were gathered:

- It was decided that the scope of the project needed to be expanded beyond Abandon Ship to handle all emergency situations. This meant more endpoints to cover common muster points beyond just the lifeboats.

- The administrative challenges of building the POB into the muster system needed to be addressed. Originally, an exported list from the vessel’s Global Management System (GMS) imported into the muster system was used, with plans to integrate with GMS in the future. However, it was quickly determined that integration with GMS was a necessity for both accuracy and efficiency.

- A virtual machine was required to handle the server portion. During the pilot, an old laptop was used and the crew struggled with the reliability of the device.

- A solid wireless infrastructure was important to keep the devices online as long as possible for global insight to the complete muster progress from anywhere. This also had an additional advantage to the rig, as it gave the it better wireless coverage for other purposes. It was determined that Cisco outdoor wireless APs would be added to the system to handle this. For the endpoints, they would be v-lan tagged so that all muster devices could be isolated for security and priority.

The pilot phase was not completely pain free, and definitely involved a few challenges that needed to get solved along the way. “We didn’t start with a known package that could be ordered, shipped, installed and put online,” Captain Oscar dos Santos says, and points out that this was due to being a test bed and that Savance wasn’t necessarily given much info up front to work with.

"I would strongly recommend Savance to other rigs in our fleet. We were using a paper muster system prior to this system’s implementation, and the improvements are immense. This is definitely the way to go!"

Other issues were caused by a lack of certain types of personnel onboard the rig. For instance, Captain Hargreaves explains that they no longer have dedicated IT professionals assigned to the rig, and that this caused some delays and problems during implementation. For this reason, ET’s were able to put together the hardware side of the system, but experienced some difficulties getting the system operational due to IT issues. After the Savance team had made every effort to assist remotely, “[the issues were finally] solved by having Mr. Steve Bardocz gain the required training to come offshore and come out to the rig to get the system up and running,” Captain Hargreaves says. “After this visit, we had a fully functional system in very little time.”

During his visit to the rig, Steve Bardocz worked closely with personnel from the Inspiration to ensure everything functioned as intended. Radio Operator Ken Davis describes: “[Steve] and I worked together along with some other guys from the rig for several days to make everything function as needed. Steve’s knowledge of the system and hard work really paid off.”

Captain Hargreaves adds that he appreciated Savance’s patience throughout the process, which, due to being a pilot program on a working rig, was slow “Steve seemed to understand that this was a pilot system and never seemed to get frustrated with the issues that would arise or the fact that a working rig often had to put the pilot program low on the priority list. [The end result] was a nearly perfect system for our needs.”

Ken Davis agrees, and says: “I would strongly recommend Savance to other rigs in our fleet. We were using a paper muster system prior to this system’s implementation, and the improvements are immense. This is definitely the way to go!”

Each lifeboat is equipped with a custom muster tablet and proximity card enclosed in a Pelican case

The Complete Solution

By streamlining the entire mustering process, the final digital emergency management system leverages technology to the fullest. In short, each person on the rig is given an RFID identifier in the form of a silicon wristband (preferred method) or a proximity card. This allows them to quickly identify and account for themselves at one of several muster points throughout the rig, based on the emergency situation and where the person is located at the moment of the incident. From the bridge or other areas of the rig, visibility into the rig muster is instantaneous through a large screen display, without phone calls, radio, or physical headcount. As a backup, if a person is not wearing their wristband or carrying their badge, their name can be selected from the touchscreen device when checking in to a muster point.

Custom wall-mounted muster station with rugged tablet, PoE, and RFID reader. » Learn more

Each of the check-in devices used on the Inspiration were custom-designed for the rig environment, and are powered through Power Over Ethernet (PoE). This allows a single Ethernet cable to both power the device and connect it to the internal network. As a backup failsafe, the devices also connect to wireless, and are battery-operated with a battery that lasts over 6 hours. Additionally, the custom-designed systems were built on a ruggedized tablet designed to operate in a wide range of temperatures and humidity levels, and were also designed to be sunlight readable. These qualities make them ideal for use as endpoint devices for the e-mustering process. A proximity card reader is attached to the unit to provide the quickest possible check-in. Finally, each lifeboat tablet is mounted in a custom-designed Pelican enclosure designed to hold both tablet and prox reader.

Large screen display showing real-time status updates from each muster point

One of the Inspiration’s criteria for an electronic mustering solution was a way to quickly communicate required information to the command team on the bridge in an understandable form. This was accomplished through a large master screen that allows for easy tracking of each muster site, and where personnel can view the progress of the ongoing muster in real-time. Captain dos Santos is one of the people who appreciates this feature: “The most attractive feature of the system is the availability of real-time updates and the display on the master screen on the bridge,” he says. “You can immediately identify the individuals that have not mustered on the master screen.”

Radio Operator Ken Davis agrees. “Before implementing this system on the Inspiration, I was excited about the thought of faster, more efficient emergency musters. We’ve been using it for several months now and the system has exceeded my expectations. The most attractive feature for me is the big screen TV mounted above the laptop I use on the bridge. It’s an extremely effective tool.”

"The most attractive feature of the system is the availability of real-time updates and the display on the master screen on the bridge. You can immediately identify the individuals that have not mustered on the master screen."

As a radio operator on the Inspiration, one of Davis’ responsibilities is to ensure that the rig always has an up-to-date Persons on Board (POB) list. This is crucial when it comes to a potential emergency situation. After an integration with the rig’s Global Management System – something that was originally planned as a future step – the process of creating an up-to-date POB list is much more efficient than the earlier plan of importing a GMS list into the EIOBoard muster system. Now, when a person arrives on the rig via helicopter, the radio operator accepts them in GMS, which then alerts the EIOBoard Emergency Mustering software of the change to the POB. As people leave, there is a similar process in GMS where the radio operator removes people, again alerting EIOBoard of the change to the POB. This way, the active muster roster list is kept up-to-date without additional work required by the radio operator.

"Savance, with the help of our IT support in town, was able to integrate the E-Muster system with our GMS, which makes updating of the E-Muster system with personnel onboard automatic."

“When we first started to install the system, it appeared as if the adding and removing of personnel from the system for crew-change was going to be considerably onerous for the rig’s radio operator,” Captain Hargreaves explains. “[However,] Savance, with the help of our IT support in town, was able to integrate the E-Muster system with our GMS, which makes updating of the E-Muster system with personnel onboard automatic.”

Results & Benefits

In short, the Inspiration’s new electronic mustering process offers a faster, more efficient, and more reliable way to account for people than the previously used methods. It provides real-time insight and better visibility to where people are located, empowering the captain and others to make better-informed decisions. Collaborative, real-time information is available from anywhere, resulting in greater visibility for everyone involved. This accuracy and accessibility to location and headcount could mean the difference of several lives when presented with a real emergency. “I jokingly refer to it as the culmination of my life’s work,” Captain Walker says.

“The main difference between using the Savance system compared to other mustering systems is that after the first stage muster if people are missing, you can identify them immediately,” Captain Hargreaves says. “Unlike in the past, muster during drills is almost an afterthought. It occurs almost automatically, and I can focus my efforts and those of the bridge team on addressing the emergency.”

"Unlike in the past, muster during drills is almost an afterthought. It occurs almost automatically, and I can focus my efforts and those of the bridge team on addressing the emergency."

Captain Hargreaves adds that both he and Captain dos Santos have experienced true emergency musters since the installation, and that they had musters in less than 10 minutes on both occasions. “One of those emergencies took place at 0200 in the morning, and involved significant emergency response and the confusion that comes along with it,” he says. “Still, muster was completed in about 8 minutes. If you would have told me this before the installation of the E-Muster system, I would have thought you were lying.”

In Captain Walker’s mind, the most important outcome is the ability to handle people who are not in their “assigned” muster location: “[The system] has the potential to save lives in a real emergency by tracking personnel who aren't where they are expected to be, and it can be updated efficiently as soon as personnel arrive or depart the vessel.”

Captain dos Santos agrees. “The flexibility of relocating from one muster point to the next is one of the most important outcomes so far. The system automatically removes you from your previous muster location and assigns you to your new location once you re-scan,” he says.

Although all crewmembers mention seeing an improvement as far as muster times go, everyone agrees that the biggest improvement is the additional visibility and the real-time information on who has or has not mustered, as well as each person’s location. “I would say our muster times are 20-25% faster on average,” Ken Davis says. “[However,] the biggest benefit by far is our ability to see how many people have mustered in each specific location, as well as the names of those people. The capability of the system to adjust a person’s mustered location if they scan in then move to a different location and scan in again is very valuable.”

Electronics Technician Victor Alford agrees: “I can see a minimum of a 25% faster mustering time,” he says. “But beyond that, we are able to see where everyone is in real-time over the wireless network. It will make things efficient in the event that we have a real emergency and need to abandon the rig.” Alford also mentions the additional bonus of increased communication. “It gives the rigs another way of communicating that we have or do not have a full muster,” he explains. “With the E-Muster system everyone at the mustering areas can assist with getting a full muster because they can see people checking in at a real-time pace.”

Jerald Colbert, also an Electronics Technician, brings up the time cut out by being able to remove the phone calls from each location: "Personally the most attractive thing about the system was the availability of real-time updates for all muster takers," he says. "They can know what exactly is going on at their and other locations as far as missing and/or checked in personnel. It eliminated the time of calling in your muster from each location and limited the requirement of human involvement, which I feel reduced the potential for errors." Another time-saving aspect, Captain Walker adds, is that time and manpower looking for mistakenly missing personnel is minimized or eliminated.

When asked what he would tell other rigs about the electronic mustering system, Captain Hargreaves says: ”Much of my correspondence with other vessels is with their captains, and I would only have to tell them one thing to sell this product: For me, musters during drills and emergencies are nearly stress free.”

Victor Alford adds: “I would like to see this E-Muster system on every vessel in our fleet. If it will save even one person’s life in the event of a real emergency, then all our hard work has been worth it.”